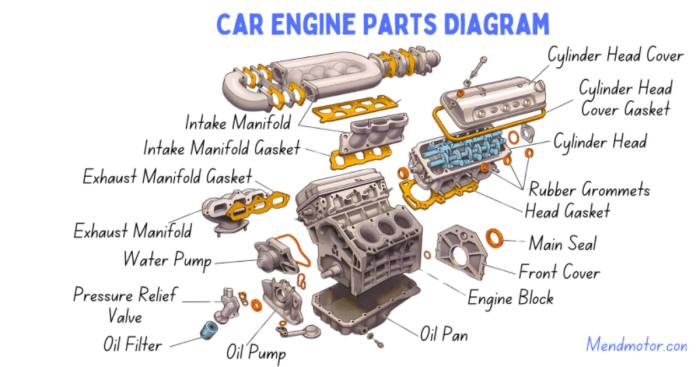

Car engine parts diagram serves as a crucial tool for both mechanics and car enthusiasts, offering a comprehensive view of the complex machinery that powers our vehicles. By understanding the layout and functions of various engine components, one can appreciate how these parts work together to ensure optimal performance and efficiency.

Notice BMW M4 Competition xDrive for recommendations and other broad suggestions.

As we delve into the intricacies of an engine, we will explore the essential components, their roles, and how a well-structured diagram can aid in diagnosing issues and planning maintenance. From the pistons that create power to the cooling systems that keep temperatures in check, each part plays a vital role in the engine’s overall functionality.

Obtain access to Vehicle registration process to private resources that are additional.

Introduction to Car Engine Parts: Car Engine Parts Diagram

Understanding car engine parts is essential for anyone interested in automotive mechanics. The engine is the heart of a vehicle, and knowledge of its components can aid in troubleshooting, maintenance, and enhancing performance. Each part plays a critical role in the engine’s operation, from generating power to ensuring efficiency and emissions control.

The primary functions of engine components include the conversion of fuel into energy, the movement of pistons within cylinders, and the regulation of temperature and pressure. Key parts found in an engine include the pistons, crankshaft, camshaft, valves, and various sensors and electrical components. Familiarity with these elements allows one to appreciate the complexity of engine design and the innovation behind modern automotive technology.

Overview of the Car Engine Parts Diagram

A typical car engine parts diagram provides a visual representation of the various components that make up an engine. It typically illustrates the layout and connection of parts, aiding in understanding how they interact during operation. The diagram often includes vital components such as the cylinders, pistons, crankshaft, camshaft, intake and exhaust valves, and the fuel delivery system.

When creating your own engine diagram, it is important to follow a clear and organized format. Start by labeling each part accurately and ensuring the connections between components are easy to follow. Use distinct colors or shading to differentiate between types of systems, such as the fuel system, cooling system, and electrical system.

Components of a Car Engine

The major engine parts, including pistons, crankshaft, and camshaft, have distinct functions:

- Pistons: Move up and down within the cylinders, creating pressure that drives the crankshaft.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, which ultimately powers the vehicle.

- Camshaft: Regulates the opening and closing of the intake and exhaust valves, ensuring the proper timing of air and fuel intake.

Different engine types exhibit similarities and differences in these components. For instance, a V8 engine has eight cylinders arranged in a V configuration, while a straight-six engine has six cylinders arranged in a single line. The materials used in various engine components also vary; for example, pistons are often made of aluminum for lightweight performance, while crankshafts are typically constructed from forged steel for strength and durability.

Engine Cooling System

The cooling system is critical in maintaining engine performance by regulating the temperature of the engine and preventing overheating. Its components include the radiator, water pump, and coolant passages within the engine block.

The flow of coolant works as follows:

Coolant absorbs heat from the engine, circulates to the radiator where it is cooled by airflow, and then returns to the engine to repeat the process.

A flowchart can illustrate this cooling process, showing how coolant flows through the radiator and into the engine, highlighting the role of the water pump in maintaining circulation.

Engine Fuel System

The fuel system is responsible for delivering the correct amount of fuel to the engine. Key components include fuel injectors, which spray fuel into the combustion chamber, and fuel pumps, which transport fuel from the tank.

The steps involved in fuel delivery can be summarized as follows:

- Fuel is drawn from the tank by the fuel pump.

- The fuel travels through fuel lines to the fuel injectors.

- The injectors atomize the fuel and spray it into the intake manifold or directly into the combustion chamber.

Direct fuel injection systems deliver fuel directly into the combustion chamber, whereas indirect systems inject fuel into the intake manifold before it enters the cylinder. This distinction impacts fuel atomization, combustion efficiency, and emissions.

Electrical System in Car Engines

The ignition system is a vital part of the electrical system, responsible for igniting the air-fuel mixture in the combustion chamber. Key electrical components include spark plugs, ignition coils, and wiring connections.

Sensors also play a crucial role in engine performance, providing data to the engine control unit (ECU) to optimize fuel delivery and ignition timing. An engine’s electrical wiring diagram visually represents the connections between these components, aiding in troubleshooting and repair.

Maintenance of Engine Parts

Common maintenance practices for car engine parts include regular oil changes, air filter replacements, and checking fluid levels. These tasks help ensure smooth engine operation and longevity.

When troubleshooting engine performance issues, some steps include:

- Checking for error codes using a diagnostic scanner.

- Inspecting spark plugs for wear and carbon buildup.

- Examining fuel filters for clogs.

Routine engine inspections should include a checklist that covers fluid levels, belt conditions, and visible leaks to preemptively address potential problems.

Innovations in Engine Technology

Recent advancements in engine parts have led to enhanced efficiency and performance. Technologies such as turbocharging, variable valve timing, and lightweight materials significantly improve power output and fuel efficiency.

The role of hybrid and electric components is increasingly significant in modern engines, allowing for reduced emissions and improved fuel economy. A comparative table of traditional versus modern engine systems shows differences in performance, efficiency, and emissions standards, highlighting the industry’s shift towards sustainable solutions.

End of Discussion

In conclusion, mastering the Car engine parts diagram not only enhances your understanding of automotive mechanics but also empowers you to take better care of your vehicle. By recognizing the interplay of engine components, you can identify potential problems and apply effective maintenance strategies, ultimately extending the life of your engine. Whether you’re a professional mechanic or a curious car owner, having a solid grasp of these concepts will serve you well.